- Home

- Shop By Car

-

Shop by brand

- ACL

- AEM

- Akrapovic

- AMS PERFORMANCE

- ARP

- ATI

- AUTOMATIC TRANSMISSION FACTORY

- BC Forged

- BC Racing

- BMC

- BP Autosports

- BRIAN CROWER

- BT INNOVATIONS

- CARRILLO

- CLUTCHMASTERS

- COBB

- COMETIC

- CP PISTONS

- DBA

- Deatschwerks

- Dragy

- DRIVESHAFT SHOP

- Eagle

- EBC

- ECUMaster

- ECUTEK

- EXTREME TURBO SYSTEMS

- Fabspeed

- FERREA

- Fore Innovations

- Fluidampr

- FUEL INJECTOR CLINIC

- Fuelab

- FuelTech

- Garrett

- Gates

- Goodridge

- GREDDY

- GSC

- H&R

- HALTECH

- Hawk Performance

- HKS

- Induction Performance

- INJECTOR DYNAMICS

- IPD Plenums

- K&N

- Kaaz

- KELFORD

- Koyo

- KW

- MANLEY

- McGard

- Mickey Thompson

- Mishimoto

- MoTeC

- NISSAN

- OS Giken

- PHR

- PRECISION TURBO

- ProEFI

- R&R RACING PRODUCTS

- RPS

- RaceGrade

- RADIUM

- Rife Sensors

- Real Street Performance

- Seibon

- SPL Parts

- ShepTrans

- Soul Performance

- Stoptech

- T1 Race Development

- Tanabe

- Tein

- TiAL

- Toyo Tires

- Toyota OEM

- Turbosmart

- Velgen Wheels

- Walbro

- Weldon

- Weld Wheels

- XS Power

-

Shop By Category

- Honda / Acura

- XFWD

T1 Race and Development - GT1R CNC Oil Pan for Nissan GTR R35 VR38

$795.00

Description

T1 Race and Development - GT1R CNC Oil Pan for Nissan GTR R35 VR38

Nissan did an amazing job with the VR38 engine, in stock form it does just about everything wonderfully. As conditions change, some shortcomings start to show and must be dealt with in order to retain reliability.

At high engine speeds (over 7500rpm), there is considerable windage in the crankcase. This causes aeration in the oil and the result is the oil pump ingesting air bubbles rather than pure oil. When an oil pump takes in air instead of oil, it is NOT GOOD for the engine.

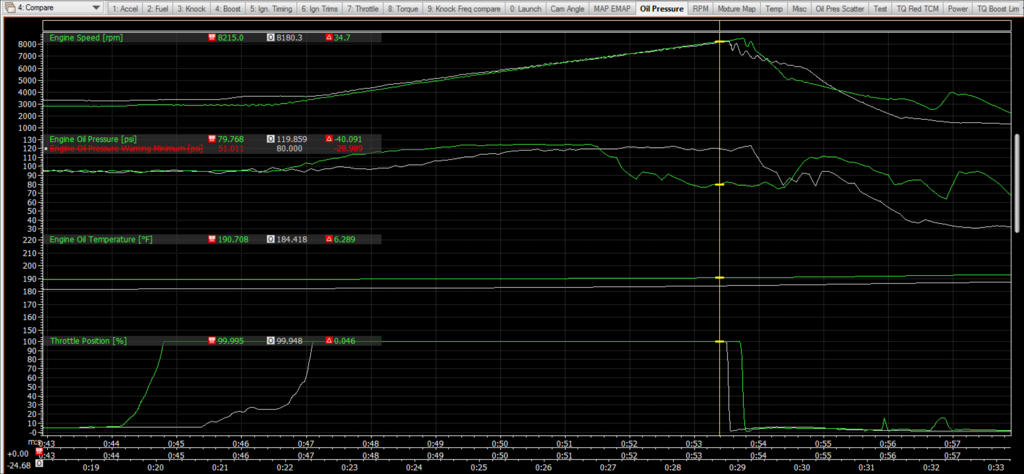

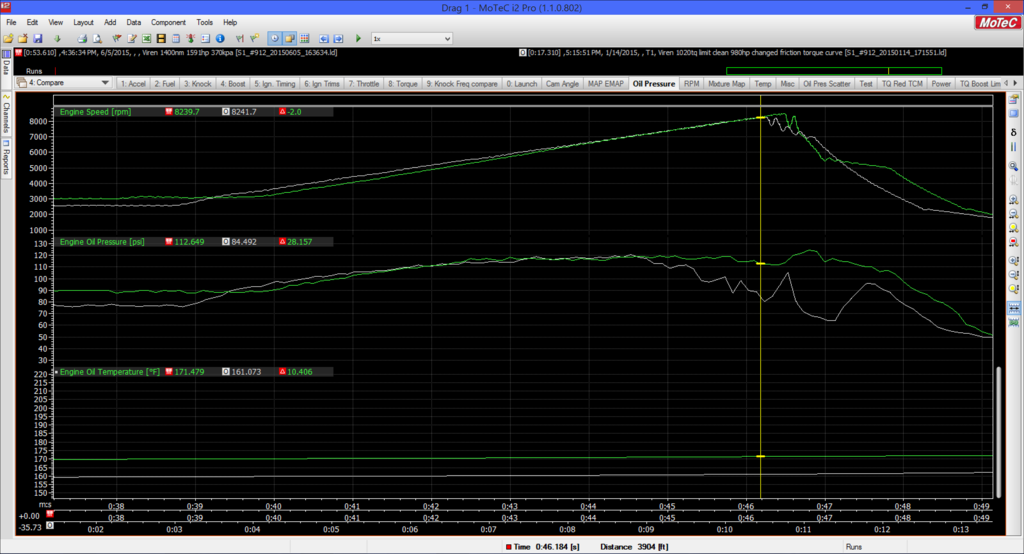

Below you can see two examples of the difference in oil pressure at higher RPM before and after this kit is installed. Both tests were performed in house on two of our cars.

Another shortcoming with the stock pan is under high G’s, the oil is forced away from the oil pickup and again, you get air instead of oil.

Most very high performance applications use a dry sump oiling system, which prevents these problems. Unfortunately changing the VR38 over to a dry sump oiling system is a very big and expensive job, so it’s not ideal for many people. The GT1R CNC oil pan and pickup adaptor is a great alternative.

We began development of this oil pan in early 2015, with various sheet metal samples being built before finalizing the design and moving it over to a CNC piece. By increasing the depth of the pan and optimizing the oil pickup location, we were able to increase the capacity by 1.5 quarts and get the oil pickup into a better position for high G acceleration.

The pan requires trimming the first layer of the plastic underpanel that goes under the oil pan. This panel has two layers, so the bottom layer stays in tact and fully covers the oil pan.

This kit includes the GT1R CNC Oil Pan and CNC Oil Pickup Adaptor. The oil pickup adaptor replaces the factory gasket with an o-ring on each end, for improved sealing and ease of install, and includes all new hardware necessary.

**Note – this oil pan CAN be installed with the engine still in the car. The rear pan bolts are close to the sub-frame. They are easiest accessed using a low profile ¼” drive swivel 10mm socket.